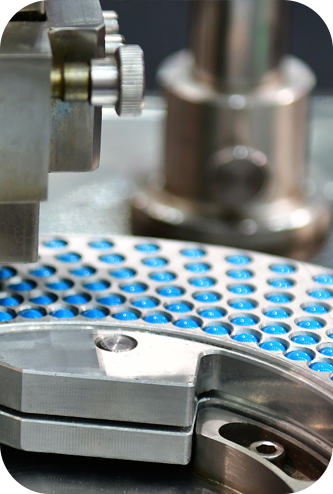

Wellness and Supplement Manufacturing Solutions

Bringing a supplement to a crowded market isn’t the hard part—making it reliably, at scale, is. Wellness and supplement companies need to deliver consistent potency across batches while navigating FDA oversight, managing supply chain disruptions, and fighting counterfeit competition.

Masked Owl Technologies partners with companies in the wellness industry that need to bridge the gap between laboratory formulations and commercial-scale production. Our approach to solutions-focused engineering helps you actually fix the source of your problems rather than just applying a one-size-fits-all bandage with standard automation and tech.

Common Challenges in Wellness Process Automation

Unlike conventional consumer products, wellness supplements face unique quality and compliance challenges that standard manufacturing approaches aren’t designed to address:

- Potency verification throughout the production process

- Cross-contamination prevention protocols

- Allergen control and validation

- Chain of custody documentation for ingredients

- Stability testing integration into manufacturing

- Consistent dosage across production runs

How MOT Brings a Different Approach

Most engineering firms approach supplement manufacturing with either pharmaceutical-grade complexity or basic food processing standards–neither of which fits the unique needs of this industry. We understand that supplement production sits in a specialized space between these extremes. MOT’s engineers aren’t tied to standard approaches from other industries or locked into relationships with specific equipment vendors. Instead, we evaluate each supplement manufacturing challenge on its own terms.

Beyond Standard Supplement Manufacturing Solutions

Many supplement manufacturing problems don’t require complex automation to solve. Our approach starts with understanding your specific formulation requirements, then building systems that make the most sense for your specific process and challenges:

- Process mapping that identifies critical control points

- Equipment selection based on formulation requirements, not vendor relationships

- Integration of testing protocols within production workflows

- Validation processes that satisfy regulatory requirements

- Custom solutions for unique supplement formats

From Scientific Formulation to Scalable Production

Companies in the wellness industry often struggle with maintaining potency, meeting regulatory documentation requirements, and handling ingredient inconsistencies. MOT supports nutraceutical process optimization by:

Data-Driven Quality Assurance for Supplement Manufacturers

Many wellness product automation systems fail because they don’t capture the right data at the right points. Supplement manufacturing requires precision monitoring that traditional systems weren’t designed to provide. Our approach begins by identifying the specific process parameters that truly affect product efficacy, then establishing targeted monitoring at these critical control points. We can also develop customized dashboard systems that highlight deviations before they become quality problems, coupled with documentation tools that support regulatory compliance. When you can see exactly what’s happening in your production process, you can make informed decisions that balance quality and output.

Build Better Supplement and Wellness Manufacturing Processes

Whether you’re moving from small-batch production to commercial scale or need strategic solutions for complex manufacturing challenges, our team provides the supplement process solutions you need to thrive in the wellness industry. Contact MOT today to discuss how our solutions-focused approach can help solve your most challenging production problems.