Bourbon Production Optimization

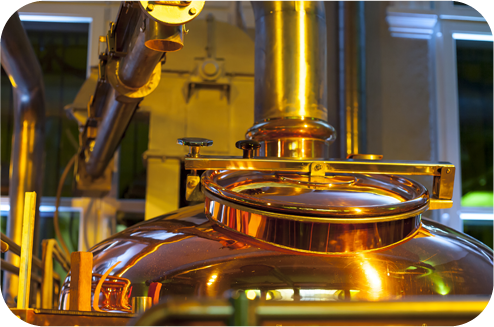

Bourbon production balances centuries of tradition with modern efficiency demands. While many providers push for extensive automation, Masked Owl Technologies recognizes that preserving your established processes is essential to maintaining product quality and consistency.

Our Solution Success team partners with you to identify targeted distillery process improvements that enhance efficiency without compromising the time-honored methods that set your products apart.

Key Production Challenge for Distilleries

Bourbon production involves distinct operational requirements:

- Meeting regulatory reporting requirements

- Maintaining product consistency across production volumes

- Managing quality control effectively

- Ensuring accurate data collection

- Balancing tradition with efficiency

- Supporting ATF compliance needs

Each facility has different needs and constraints. We help you assess current operations and develop practical solutions that deliver measurable improvements while protecting your established methods. This measured approach ensures changes support consistency and compliance without compromising the quality your customers expect.

Balancing Bourbon Distillery Automation and Tradition

Many bourbon facilities face pressure to modernize while preserving traditional processes. Through our systematic discovery process, we define the real challenges before proposing any changes–because understanding comes before solutions.

When working with distilleries, we focus on:

- Streamlining regulatory reporting without disrupting production

- Implementing reliable data collection for ATF compliance

- Managing risk throughout process changes

- Supporting consistent quality with available staff

- Enhancing production tracking and visibility

- Developing solutions that scale with your operation

Quality Control Case Study:

Targeted Solutions Reduce Waste

When a bourbon producer needed better quality control, we avoided disrupting their core production methods to solve the problem. By implementing a focused sensing system, we reduced cap placement defect detection time from 50 bottles to just 3. This automated quality inspection for bourbon maintained production speeds while significantly reducing waste, demonstrating how selective improvements can deliver substantial results.

Respect Tradition, Embrace Precision: Let’s Connect

Whether you’re facing specific production challenges or looking to improve overall distillery efficiency, our team starts by understanding your unique requirements. Contact us to discuss how we can support your bourbon production optimization while preserving the traditions that define your products.